KLINGER® Metallic and semi-metallic gaskets

Our range of metal gaskets meets the needs of all industries and applications. Typical uses include pressure vessels, such as heat exchangers and steam boilers, pipelines, and high-pressure applications.

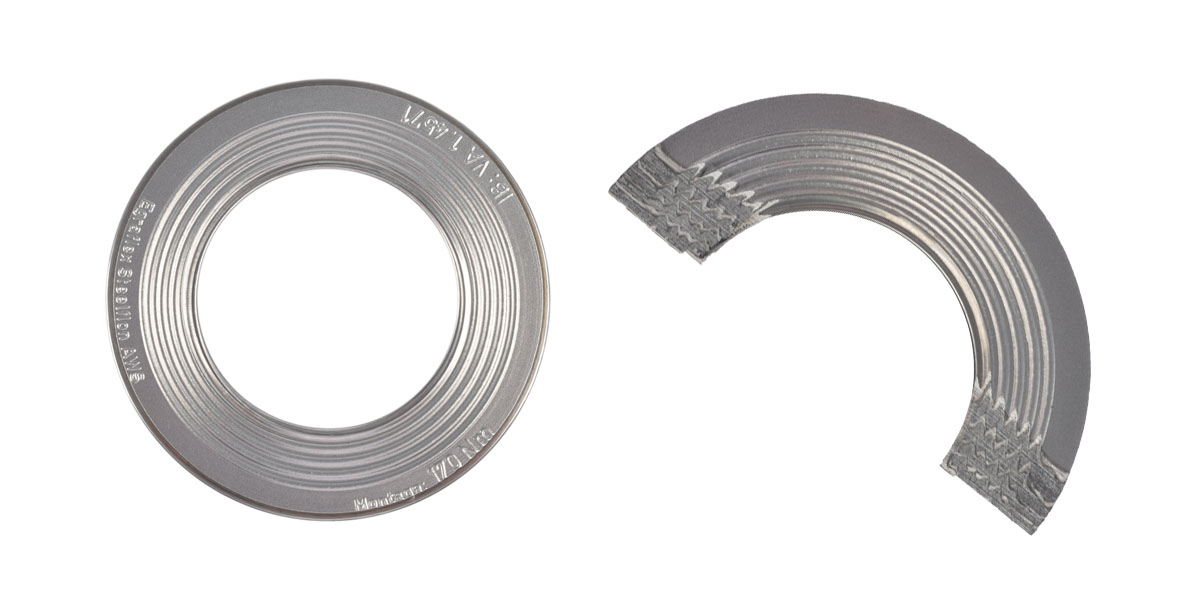

Spiral wound gaskets are the most commonly used type of metal gasket. Spiral wound and camprofile gaskets have an excellent ability to absorb load variations caused by changes in temperature, pressure, or other factors. Compared to spiral wound gaskets, camprofile gaskets offer better sealing at low and uneven bolt loads. Additionally, camprofile gaskets can be reused 3-4 times by replacing the soft facing, typically made of graphite.

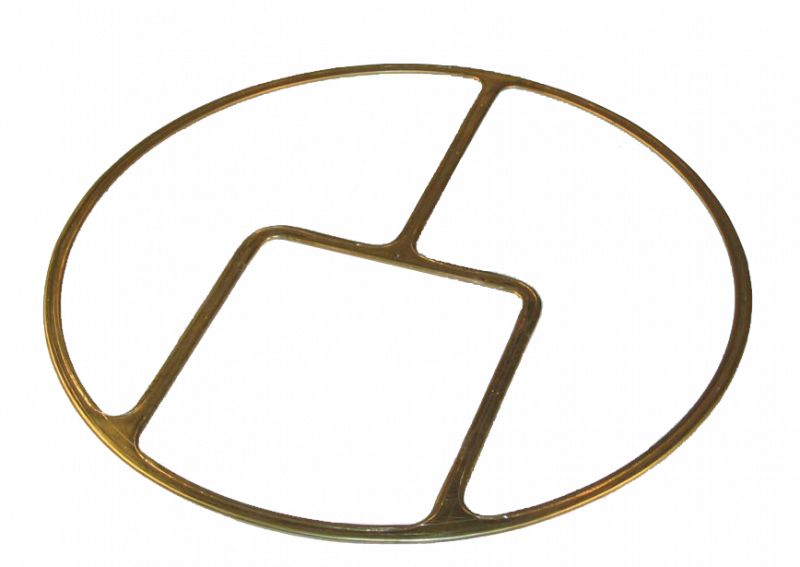

Metal-jacketed gaskets can be considered predecessors to camprofile gaskets. However, they require high surface pressure to seal, which is why camprofile gaskets have become more popular. The use of metal-jacketed gaskets may still be justified in cases where the sealing surfaces are extremely narrow.

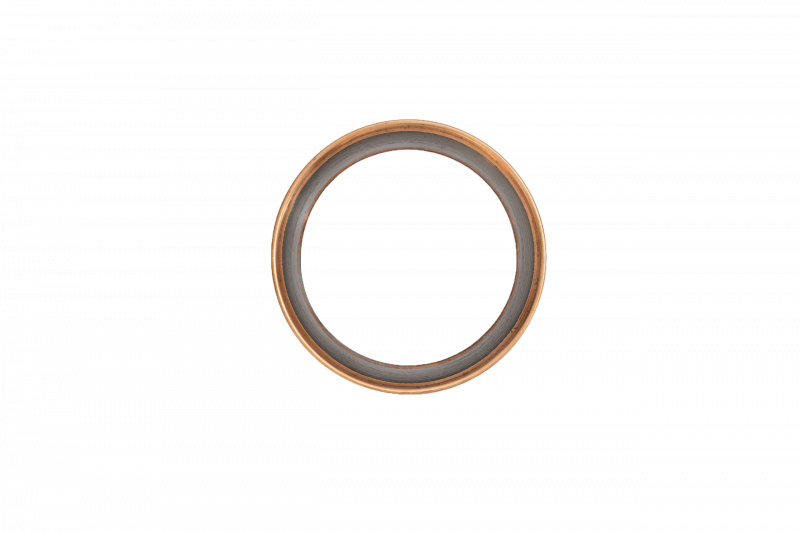

Solid metal gaskets (metallic ring joints) are typically used in applications where the pressure and temperature resistance of other metal gaskets is insufficient. The most common applications include various petrochemical processes. When selecting a gasket, it is important to choose a gasket material that is about 30 Brinell points softer than the flange material to avoid damaging the flange surfaces.