FLAT GASKETS

KLINGER® is a global leader in the research, development, and manufacturing of flat gaskets. Recognised for its high quality and reliability, KLINGER® provides premium gasket solutions that meet the most demanding industrial requirements. In our laboratory, we test the properties of flat gaskets according to various standards and customer-specific requirements. Additionally, we verify their suitability using EN1591-1 tightness and strength calculations to ensure maximum durability and performance.

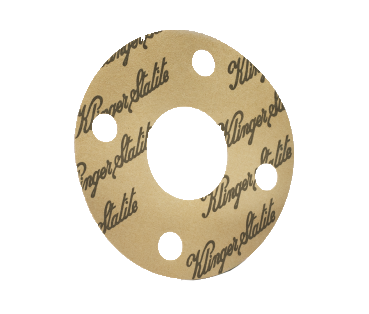

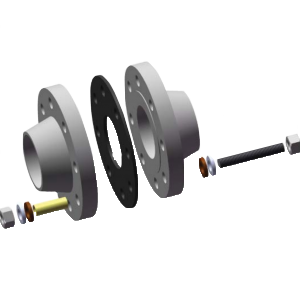

In industrial applications, the most common flange gaskets are fibre-based flat gaskets, while PTFE gaskets are widely used in chemical environments. PTFE flat gaskets are highly versatile and help optimise gasket selection. For high-temperature applications, graphite and ceramic mica gaskets are preferred, whereas semi-metallic, metallic, and spiral wound gaskets are used for high-pressure environments.

KLINGER® offers a comprehensive range of flat gaskets, designed to meet the needs of various industries, ensuring reliable sealing performance and long service life.

Discover our product range

High-quality KLINGER® gasket materials for industrial needs

Our most sought-after gasket sheet materials include the unique KLINGER® top-chem 2000 (PTFE), KLINGER® MLX (graphite) and KLINGER® Quantum (fibre).

- KLINGER® top-chem 2000 is the only Fire-Safe-approved PTFE gasket suitable for industrial use that can withstand temperatures exceeding 200°C both in practice and according to EN1591-1 calculations.

- KLINGER® MLX (graphite) meets nuclear-grade cleanliness requirements and is TA-Luft certified, offering excellent sealing performance.

- KLINGER® Quantum is designed to improve resistance to heat and chemicals by using HNBR as a binder instead of conventional NBR. In addition, it is FDA-approved, making it ideal for a wide range of industrial applications.

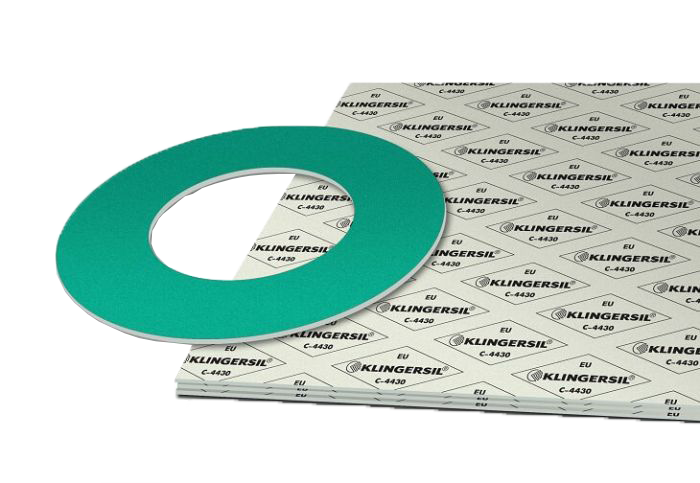

KLINGERsil and other KLINGER® materials as reliable choices for maintenance

Some of our most well-known gasket materials include KLINGERsil® C-4430, commonly referred to in maintenance as “Klingerite”. Additionally, Maxiflex spiral wound gaskets, Sealex sealing tapes, and TopLine packings have established themselves as reliable solutions for maintenance and operational reliability.

Our product range also includes various specialty materials, such as thermal insulation, wear protection, and spray shields, designed to enhance safety in demanding industrial environments.

The high quality and safety of KLINGER® gasket materials are ensured by the ISO 9001 quality management system and the ISO 14001 environmental certification. The entire production process meets and exceeds the industry’s strictest quality standards, guaranteeing superior performance and durability.