In addition to KLINGER’s own materials, we can also cut other market-available materials. We use CAD technology and have extensive cutting capabilities, including water, laser, plasma, and computer-controlled mechanical cutters.

Sustainable development and eco-friendly solutions

We are committed to sustainable development and eco-friendly practices. In the gasket cutting process, we focus on minimizing waste and continuously develop new methods and services to reduce waste production.

Our production planning in the cutting shop is constantly evolving, and we guide customers in selecting gasket materials that reduce volume spread and waste growth. This approach allows us to provide more efficient gasket solutions.

Unique gaskets

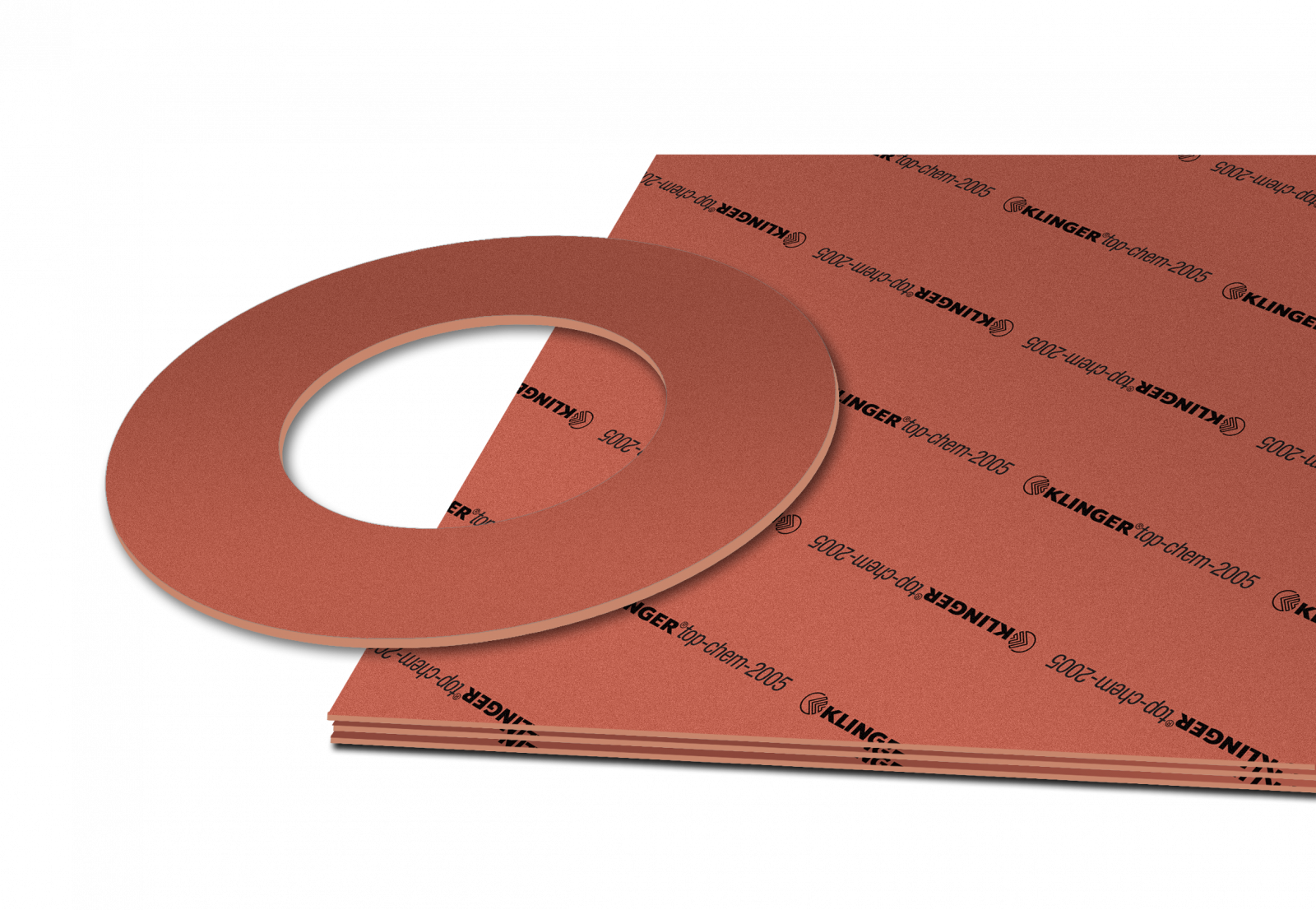

KLINGER’s gasket materials, such as the unique KLINGER® top-chem 2000 (PTFE), KLINGER® MLX (graphite), and KLINGER® Quantum, are among the best solutions on the market for demanding applications. For example, KLINGER top-chem 2000 is FireSafe certified and suitable for all chemicals in extreme temperatures, while KLINGER Quantum offers superior resistance to heat, chemicals, and harsh conditions compared to competing fiber gaskets.

Gasket material standardization

Many of our customers have a variety of gasket products from different suppliers in their inventory, and the equivalence of gasket materials may not always be clear. We offer a standardization service that helps customers optimize gasket material use, improve workplace safety, and achieve economic benefits.

Expertise and training

We also provide flange connection training, increasing gasket knowledge and promoting environmentally and economically sustainable collaboration.