PALLETIZING AND MARKING AUTOMATION

Universal Robots’ collaborative robots (cobots), combined with KLINGER Finland’s product marking solutions, offer an efficient and flexible comprehensive solution for the palletizing and marking automation needs of the packaging industry. With UR cobots, companies can automate repetitive and time-consuming tasks, increasing productivity and improving working conditions.

The benefits of cobots in enhancing palletizing and product labeling automation

Using cobots for palletizing tasks enables fast and precise handling of products, reducing errors and improving production line efficiency. Collaborative robots do not necessarily require safety fences around them, thus saving floor space. They can handle various products and easily adapt to production changes. Since cobots are designed to work in the same workspace as humans, leveraging palletizing and marking automation is easier for companies of all sizes.

In product marking automation, UR collaborative robots ensure accurate and consistent marking, reducing the risk of incorrect markings and improving product traceability. Cobots’ programming is intuitive, and their deployment is quick and effortless.

Reliable collaborative robots to enhance your company’s competitiveness

UR cobots offer a reliable and cost-effective way to improve palletizing and marking automation in production processes, helping companies stay competitive and meet the growing demands of the market.

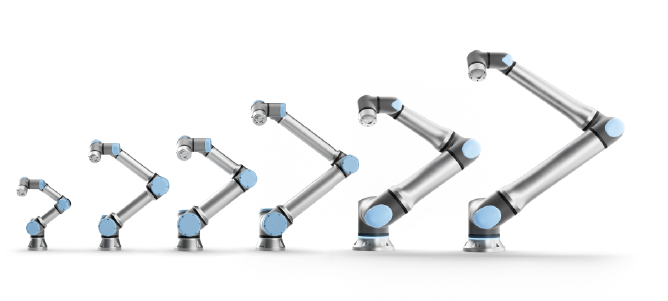

Universal Robots’ mission is to make automation accessible to everyone, everywhere. Over 75,000 cobots have been deployed worldwide, and they are developed and manufactured in Odense, Denmark. Universal Robots is a clear market leader and pioneer in collaborative robotics, and the new fifth-generation cobots have taken the technology to a new level.

KLINGER Finland helps you choose the collaborative robot solutions and necessary accessories that best support and enhance your production.