LASER MARKING

CO2 laser technology

The operating principle of a CO2 laser is based on the excitation of carbon dioxide molecules. Inside the laser, there is a tube filled with carbon dioxide and other gases, such as nitrogen and helium. The molecules in the tube are brought to an excited state by passing a high electric current through them or stimulating them in other ways. This excitation causes the atoms in the carbon dioxide molecules to release energy, making them vibrate rapidly.

This vibration creates an energy discharge that emits light. The light travels through the tube using mirrors and eventually strikes an optical lens embedded in the laser, which focuses the light into a single point. This powerful laser beam can then be directed and utilized in a wide range of applications.

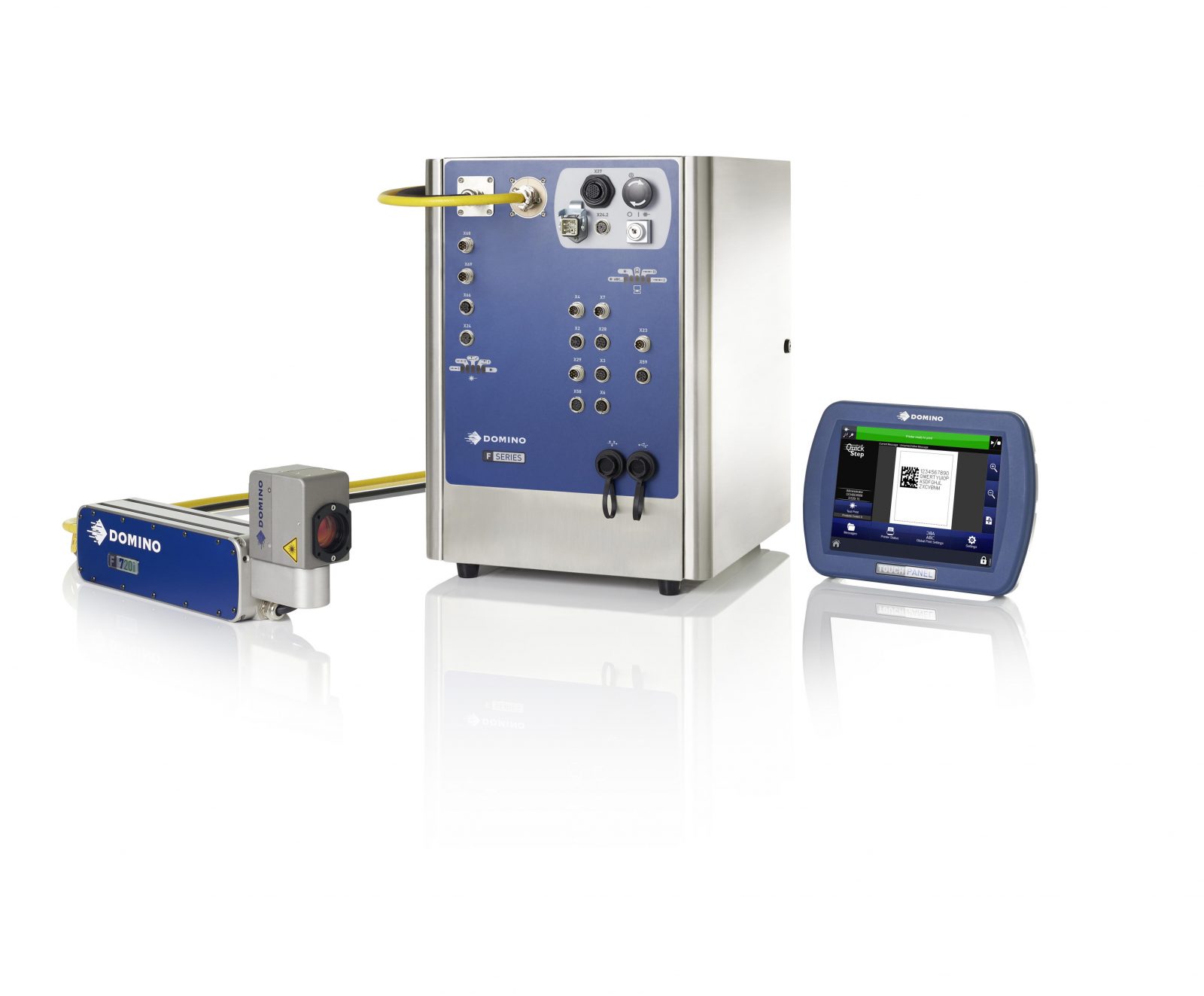

Advanced fiber laser technology

The operating principle of a fiber laser is based on stimulated emission of laser light. Inside the laser is a long, thin fiber with mirrors at its ends that allow the laser light to reflect back and forth through the fiber. One end is also coated with a partially transparent mirror. When energy is supplied to the laser, the atoms in the fiber reach an excited state.

This excitation triggers the emission of light, which travels back and forth through the laser fiber and eventually strikes the partially transparent mirror. This mirror reflects part of the light back, where it interacts with the excited atoms again, stimulating them to produce even more light. This process continues, amplifying the laser light until it finally passes through the partially transparent mirror, forming a laser beam.

Fiber lasers are capable of producing extremely powerful and precise laser beams, making them suitable for a wide range of applications, including material marking, engraving, and color modification.