Hydrogen-related standards and legislation are still developing, and most hydrogen projects are still in the planning phase. The process industry supplier, KLINGER Finland, is now urging companies to focus on safe gasket and valve selections.

KLINGER Finland is a solution provider for sealing and valves in the process industry. In addition, their product range includes labeling devices, monitoring systems, and machine automation sensors and motors. KLINGER Finland Oy is part of the international KLINGER Group.

– We are one of the few companies that manufactures gasket materials and valves ourselves, and we can combine this expertise, says Sales Manager Jukka von Hertzen.

Regarding hydrogen-related solutions, the company aims to be a pioneer and is one of the first players to have experience in sealing a Power-to-X hydrogen plant. Additionally, the company’s products are being used in the high-pressure hydrogen line of a project.

Sales Director Axel Barman observes that the rapidly evolving hydrogen market is still in a transitional phase, particularly in terms of standards. Companies and experts with genuine experience in handling hydrogen are still few and far between.

– New concepts emerge weekly, but the situation regarding concrete solutions being used is still quite unclear. The legislation is still developing, and hydrogen has never been handled on this scale before.

Customers Must Demand Sufficient Testing

According to Barman, in the past, the tightness levels of gaskets were not typically compared closely. However, with hydrogen, this is critically important. Hydrogen, being a small molecule, is challenging to seal and can pose a significant safety risk.

– A hydrogen leak can create a hazardous situation. Even when the leak doesn’t pose a direct risk, it represents a cost risk. At the plant level, gasket selections can result in an annual difference of thousands of cubic meters in emissions.

For this reason, testing gaskets is absolutely critical. On the bright side, gaskets have traditionally been tested with helium, whose properties closely resemble hydrogen. Therefore, helium tests can provide valuable insights into how a gasket will perform with hydrogen.

In gasket selection, you can use the gasketdata.org EN13555 values to compare the leak levels of gaskets. If a gasket does not have these values, it should not be used with hydrogen or any other medium in industrial applications.

– Gasketdata.org is maintained by a non-profit organization that compares gasket manufacturers’ products and publishes the comparison data for everyone to use, explains Barman.

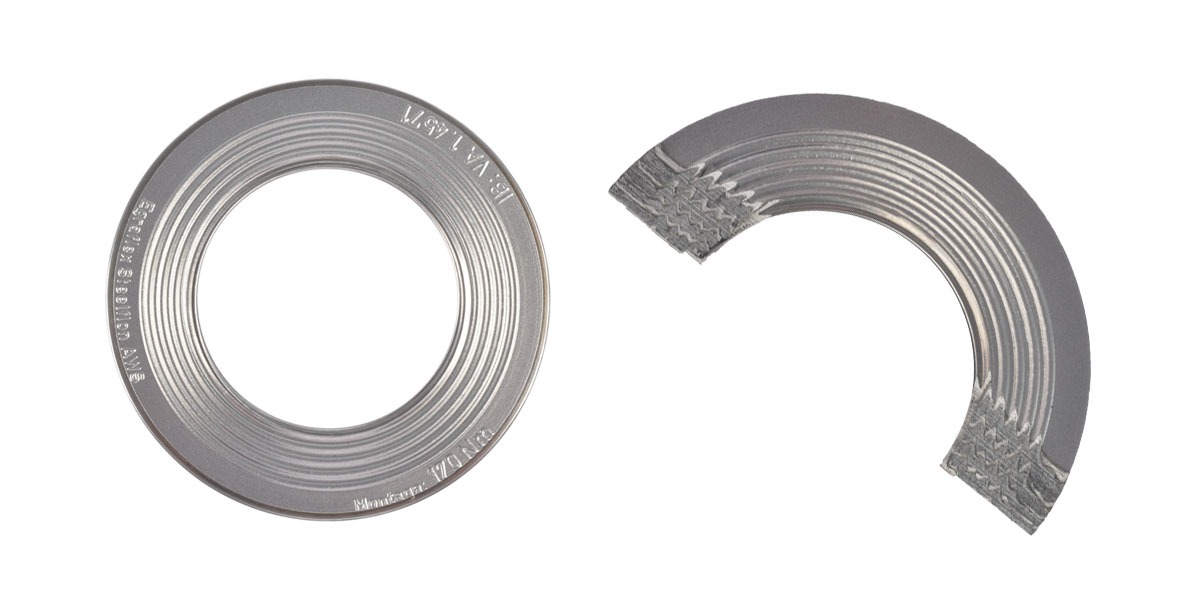

KLINGER WLP Waveline is the tightest gasket in the gasketdata.org database. The difference in leak level compared to a traditional flat gasket is over a thousandfold.

– Customers now need to learn to compare leak levels, as the differences in hydrogen applications are far more dramatic than with many other media. Knowledge in this area is still emerging, but from a safety perspective, the importance of making the right choices is obvious, concludes Barman.

This article was originally published in the Technology and Subcontracting Solutions expert publication produced by GSD Nordic Oy, which was included as a campaign supplement in Tekniikka&Talous magazine on September 27, 2024. The campaign will also be distributed physically at the Subcontracting Trade Fair from October 1 to 3, 2024.

Come explore KLINGER Finland’s solutions at the Subcontracting Trade Fair, booth number D 9.